TPU Adhesive for Shoe-1

The adhesive used for shoemaking has evolved from early yellow rubber (chlorinated rubber), liquid glue paste (chlorinated rubber grafted MMA) to the most suitable PU adhesive today. TPU adhesive has evolved from importing TPU particles in the early days to dissolving them into PU adhesive, and now the technology of self reactive solvent based PU adhesive is very mature. China's self-developed TPU adhesive system, combined with the manufacturing technology of TPU particles, has developed shoe adhesive particles.

1. Key demand points for shoe adhesives

(1) The initial adhesive strength is good when two types of adhesive materials are applied and pressed together after drying, and the adhesive force generated immediately is called the initial adhesive strength. Generally speaking, the initial adhesive strength of PU adhesive is better than that of chlorinated rubber adhesive. Good initial adhesion and continuity in shoe processing (such as bonding and trimming) can increase production efficiency.

(2) Tack time or Tack ranqe refers to the time that adhesive can be applied to a material after it has dried, and the longer the Tack time, the more advantageous it is for processing.

(3) The adhesive force generated after a period of time after bonding is good in the later stage. If the adhesive force is strong in the later stage, the bonding effect is good and can be maintained for a long time.

(4) Good operability, easy to apply and labor-saving, with low usage. Can adapt to various operating conditions. Various tools can be used for construction.

(5) If the pot life is long and no curing agent is added, there is no problem with the pot life. When 3-5 phr of curing agent is added, the viscosity of the adhesive gradually increases, forming a gelatinized state and unable to be used.

(6) Good resistance to yellowing (including light and heat stability). When the upper or sole of a shoe is made of light colored material (especially white) and exposed to light or heat, the appearance may turn yellow, which can affect customers' willingness to purchase and reduce the overall texture. Generally speaking, PU based adhesives have much better resistance to yellowing than chlorinated rubber based MMA based adhesives.

(7) The lighter the appearance (adhesive itself and its coating) of both, the better, and it will not affect the light colored material. Some are due to customer usage habits, while others prefer transparency.

(8) Suitable for various shoe materials, the upper materials are mostly PU leather, PVC leather, genuine leather, nylon cloth, etc. The sole materials are mostly PVC sole, PU midsole, rubber sole, TPR, EVA, etc. PU adhesive has good affinity for the above materials and is a highly suitable adhesive.

Recently Posted

-

The all-round application of TPU in sports shoes: upper, midsole, outsole

December 30, 2025The all-round application of TPU in sports shoes: upper, midsole, outsoleTPU has excellent processing properties such as injection Read More

Read More -

TPU Adhesive for Shoe-3

December 27, 2025Discussion on the formula of TPU shoe adhesiveThe composition of TPU adhes Read More

Read More -

TPU Adhesive for Shoe-2

December 25, 20252. Introduction to TPU adhesive raw materials for shoesPolyol (a) Polyester Polyol ◆ is formed by esterification and dehydration o Read More

Read More -

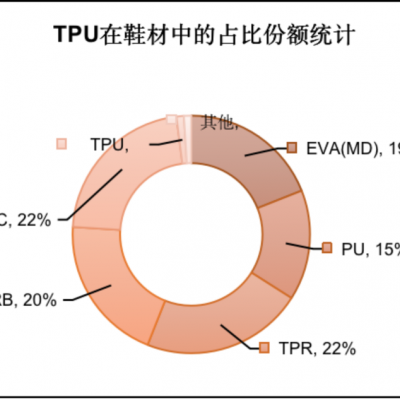

Application of TPU in Shoe Materials

December 19, 2025TPU has excellent processing properties such as injection molding, extrusion, calendering, blow molding, and compression molding. Read More

Read More